Upgrade to CULPEPER KDAT and enjoy the timeless appeal of natural wood but with added benefits.

PROCESS

After wood is pressure treated, the product is completely wet. It is then placed in a large oven (kiln) and the excess moisture is removed allowing the wood to return to its original moisture content level. This allows the wood to be stronger, stiffer and more dimensionally stable.

Drying increases the wood’s strength and minimizes tendency to shrink, cup or warp

KDAT Wood is Lighter

Paint, Stain or Seal Immediately

More Information on Culpeper KDAT

BENEFITS OF USING CULPEPER KDAT LUMBER:

- Ready to paint, stain or seal immediately

- Dried to original moisture content

- Increased strength and stiffness

- Lighter weight than freshly treated lumber

- Easier to cut, install and handle

- Minimizes the natural tendency to shrink, cup and warp

RECOMMENDED APPLICATIONS:

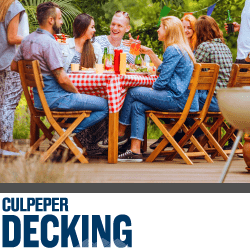

- Decks

- Trim and window casings

- Permanent wood foundation

INSTALLATION TIPS:

- Culpeper KDAT material should be kept dry before and during installation.

- Pre-drill the ends of deck boards anytime you get within the widths distance from the end of the board. This will help reduce end splitting.

- Culpeper KDAT deck boards should be gapped the width of an 8 penny nail (1/8”). This gap will allow for the normal expansion and contraction of the board. Click here for more information.

- Seal your product immediately with oil-based or hybrid stain, paint or primer.

KDAT Available Products: