- < Home

- |

- Resources

- |

- Product Education

- |

- Care & Maintenance

- < Home

- |

- Resources

- |

- Product Education

- |

- Care & Maintenance

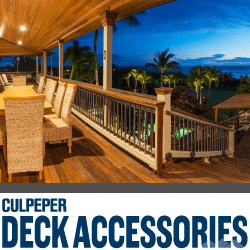

The right care and maintenance will protect your pressure treated wood from the harsh effects of weathering caused by rain, sunlight and temperature change.

The following information will help you protect your investment and get the most enjoyment and satisfaction out of your backyard.

CLEANING & MAINTAINING

A simple solution of mild soap and a pressure washer will help clean your project of surface mold and dirt. Just keep the pressure low, use a 45-degree fan and keep the wand moving so you don't damage your deck. Keep in mind that surface mold does not affect decay-resistant properties of your project.

After cleaning, paint or stain should be applied every 2 years to keep your deck looking bright and fresh for those days spend enjoying your time grilling, entertaining or simply relaxing outdoors.

HOW LONG SHOULD I WAIT TO SEAL MY DECK AFTER INSTALLATION?

In hot dry summer months, typically 2-3 weeks; in cooler months typically 4-6 weeks. For a wood sealant/finish to be effective the wood surface must be thoroughly dry. Here is a simple test. Splash water on the deck surface and observe its dispersion. If water droplets form on contact, the lumber is not yet dry enough to accept a finish. If water is absorbed into the wood it is time to apply/re-apply a wood sealant or finish.

ROUTINE WOOD INSPECTION AND REPLACEMENT

Severely warped and splitting lumber that cannot be salvaged should be replaced. It is unfortunate, but in spite of homeowners' best efforts, some pieces of wood, through the natural growing characteristics in the grain pattern, will mechanically degrade over time to become unsuitable for use.

FASTENER INSPECTION

Your regular maintenance program should include fastener inspection to determine if nails, screws or bolts are working loose. A nail that has popped out of the wood can be driven back in, and splitting boards can, in some cases, be reinforced with additional fasteners.

DISPOSAL OF PRESSURE TREATED WOOD

Pressure treated wood should never be burned in open fires, stoves, fireplaces or residential boilers. Pressure treated wood may be disposed of in landfills or burned in commercial or industrial incinerators or boilers in accordance with federal, state and local regulations.

NATURAL WOOD OCCURRENCES

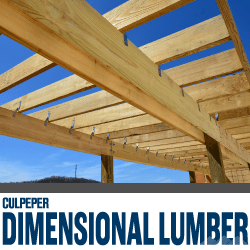

Building your project with wood from Culpeper, means your wood has proven protection against rot, fungal decay and termite attack. However, a regular maintenance program is necessary to minimize the effects of the weather. Whenever a treated wood is exposed to the weather, certain inherent properties of the wood become evident. The characteristics listed below are natural to wood and are not warranted against such occurrences. Here are examples of what can happen:

SHRINKAGE

As pressure treated wood dries, you can expect some slight shrinkage in both width and length to occur. To minimize gaps between boards, wet pressure treated wood should be butted together during installation.

SPLITTING AND CHECKS

As wood is exposed to alternating cycles of wetting and drying, some splitting and checking may occur.

BOWING, CROOKING, CUPPING AND TWISTING

Wood may bow, crook, cup or twist in varying degrees depending on stresses released by initial sawing of the lumber and moisture absorption.

COLOR FADING OR WEATHERING

When wood is exposed to natural sunlight, color fading occurs. The use of a high-quality stain will renew the desired color. A stain containing a water repellent is recommended.